Why Robotic Vision Is Vital for Advancing Precision in Production Industries

Robotic vision has become a crucial part in modern-day production. It encourages devices to evaluate aesthetic information with remarkable accuracy. This capability improves top quality control and reduces the likelihood of problems. As markets venture for higher effectiveness, comprehending the details of robotic vision comes to be crucial. The interplay between technology and operational procedures elevates vital inquiries about future innovations and their implications. What exists in advance for accuracy in manufacturing?

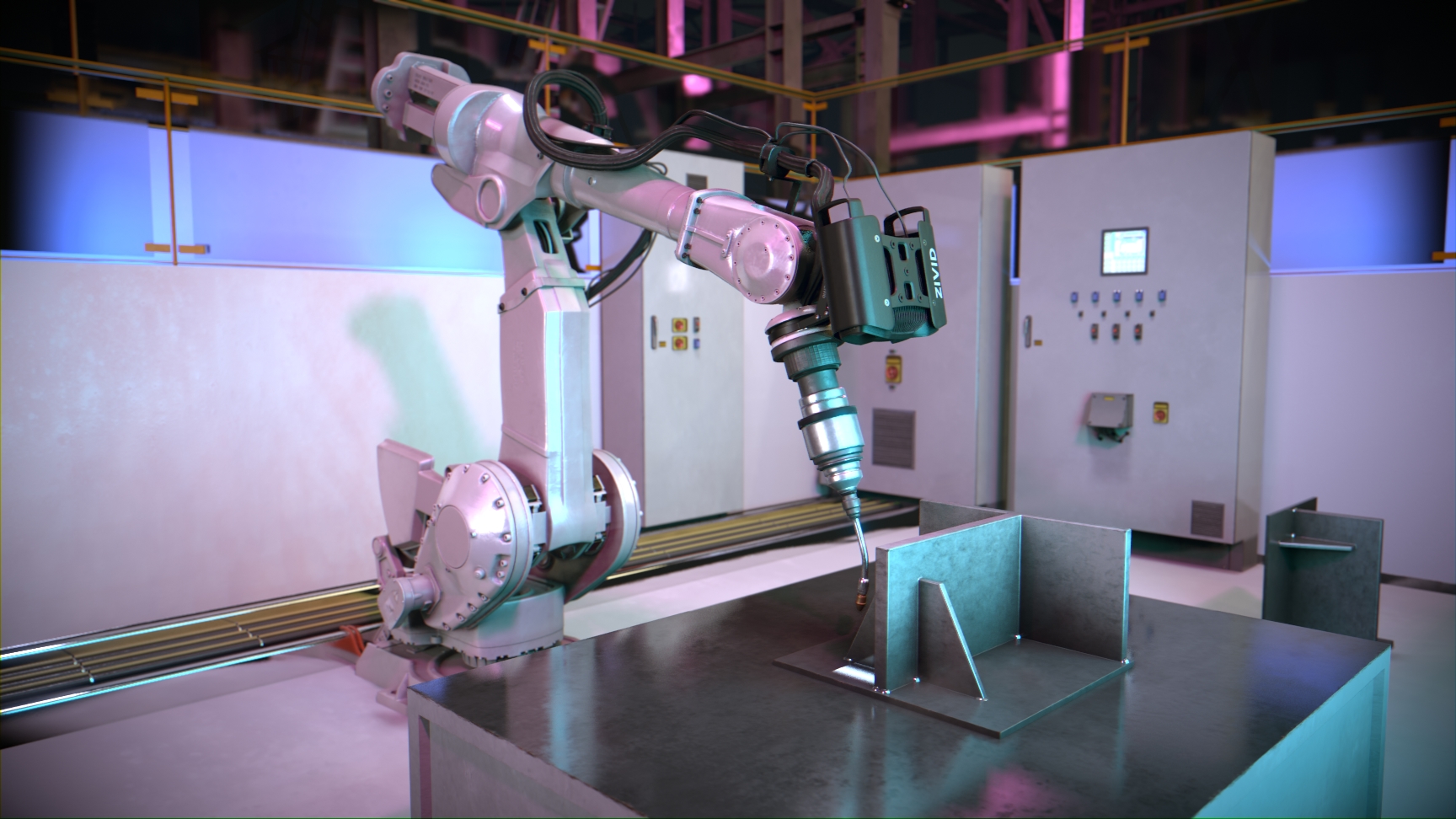

Comprehending Robotic Vision Technology

Enhancing Quality Assurance With Robotic Vision

Increasing Functional Performance Via Automation

Automating production procedures via robotic vision considerably improves production speed, permitting for quicker turn-around times. This technology also lessens error rates, making certain higher precision in procedures. Additionally, structured resource monitoring is achieved, resulting in extra efficient use products and labor.

Boosted Manufacturing Speed

While the assimilation of robotic vision in production has transformed functional processes, its most substantial benefit hinges on boosted manufacturing rate. By employing innovative photo processing and real-time data evaluation, robotic vision systems can quickly determine and respond to production demands. This sped up responsiveness gets rid of delays typically connected with hands-on examination and decision-making procedures. Furthermore, these systems can run constantly without exhaustion, ensuring that production lines maintain high throughput. The capacity to spot and attend to issues immediately better enhances workflows, permitting manufacturers to optimize output levels (optical fibre diameter analyser). Consequently, companies take advantage of decreased cycle times and increased performance, placing them competitively on the market. Boosted production speed, driven by robotic vision modern technology, inevitably leads to enhanced operational effectiveness across the manufacturing landscape

Minimized Error Fees

As manufacturing rate rises, keeping accuracy ends up being critical in manufacturing processes. Robotic vision systems substantially add to minimized mistake prices by offering exact measurements and real-time analyses. These advanced systems use high-resolution video cameras and sophisticated algorithms to spot flaws, imbalances, or disparities in products throughout setting up. By automating quality assurance, manufacturers can swiftly determine and correct problems that human examiners may forget. This not just lessens waste however likewise enhances general product top quality. In addition, the integration of robotic vision lowers irregularity in manufacturing, guaranteeing that each product meets stringent requirements. Makers experience fewer pricey recalls and enhanced consumer satisfaction, eventually leading to a much more effective and profitable operational version.

Structured Source Monitoring

Reliable source monitoring is critical for making best use of operational efficiency in manufacturing, particularly when integrated with robotic vision systems. These systems improve the capability to keep an eye on and assign sources accurately, making certain that products and fibre testing equipment labor are used effectively. By using sophisticated aesthetic technologies, producers can recognize inefficiencies in genuine time, lowering waste and boosting production timelines. Additionally, robotic vision enables precise stock tracking, minimizing the threat of overstocking or stockouts. Automation of these procedures not only streamlines operations however likewise enables human workers to concentrate on higher-value tasks, cultivating advancement and productivity. Therefore, firms can accomplish significant expense savings while keeping high-quality requirements, inevitably positioning themselves much more competitively in the industry.

Decreasing Human Error in Manufacturing Processes

Human error remains a considerable obstacle in making procedures, commonly bring about expensive mistakes and ineffectiveness. In environments where accuracy is paramount, also small lapses in judgment can lead to faulty items or delays in production timetables. Robotic vision systems can minimize these threats by supplying precise and regular tracking of making operations. By automating tasks such as quality assurance and assembly line evaluations, these systems reduce the reliance on human oversight, thereby minimizing the possibility for errors.Moreover, robotic vision technology improves data precision, enabling real-time changes based on aesthetic responses. This ability assures that any type of deviations from developed requirements are immediately determined and dealt with, additionally minimizing the likelihood of errors. As makers increasingly take on robotic vision, they can anticipate not just to boost accuracy and performance yet additionally to cultivate a much safer working atmosphere by reducing the pressure on human drivers.

The Duty of Expert System in Robotic Vision

Expert system noticeably enhances robotic vision by employing artificial intelligence formulas and advanced picture processing methods. These modern technologies allow robotics to analyze visual data with greater accuracy, enhancing both efficiency and precision in making setups. Therefore, the combination of AI into robotic vision systems stands for an essential innovation in automation.

Artificial Intelligence Algorithms

Device knowing formulas are changing robotic vision in manufacturing by allowing makers to interpret and evaluate aesthetic information with remarkable accuracy. These algorithms allow robotics to gain from large datasets, adjusting to brand-new situations and improving their efficiency in time. By leveraging strategies such as supervised and unsupervised discovering, robotic systems can determine patterns and abnormalities in real-time, which enhances high quality control and reduces waste. Additionally, artificial intelligence promotes much better decision-making processes, enabling robotics to enhance their activities based on found out experiences. As these formulas evolve, they equip robotic vision systems to execute progressively intricate tasks, inevitably driving efficiency and accuracy in making operations. The assimilation of maker understanding consequently plays a pivotal duty in the innovation of robotic vision modern technology.

Picture Processing Techniques

Enhancing the capacities of robotic vision, image processing strategies play a crucial role in allowing systems to interpret visual details successfully. These techniques involve algorithms that enhance photo top quality, extract relevant attributes, and acknowledge patterns within visual data. By using techniques such as edge discovery, segmentation, and object acknowledgment, robotic systems can determine and categorize elements with remarkable precision. The combination of artificial intelligence additionally enhances these methods, allowing for adaptive understanding and enhanced decision-making in vibrant environments. Because of this, robotic vision systems can not only identify flaws however also maximize procedures, resulting in raised performance and accuracy in manufacturing. Subsequently, the constant improvement of photo handling methods stays crucial to the development of robotic vision in industrial applications.

Future Trends in Robotic Vision for Production Industries

As sectors increasingly prioritize effectiveness and precision, the advancement of robotic vision modern technology is readied to transform manufacturing procedures significantly. Future fads suggest considerable improvements in expert system and machine learning assimilation within robotic vision systems. These renovations will boost real-time decision-making abilities, allowing robotics to adjust to differing problems autonomously. The fostering of 3D vision systems is expected to increase, offering even more precise spatial awareness and item recognition. Cooperations in between robotics and human workers might additionally develop, with sophisticated vision systems helping with much safer and extra effective interactions. Additionally, the use of side computer will likely allow faster data processing, lowering latency and improving operational responsiveness. As these trends unfold, the manufacturing sector stands to gain from improved quality assurance, decreased waste, and structured workflows, inevitably causing enhanced competition in a swiftly altering market.

Frequently Asked Inquiries

How Does Robotic Vision Differ From Standard Maker Vision Solutions?

Robotic vision integrates sophisticated algorithms and real-time processing, making it possible for vibrant interpretation and interaction with environments. In contrast, traditional equipment vision largely focuses on static image capture and evaluation, limiting adaptability and responsiveness in intricate manufacturing scenarios.

What Industries Benefit The Majority Of From Robotic Vision Technology?

Numerous industries profit considerably from robotic vision technology, consisting of vehicle, electronic devices, and food processing. These fields take advantage of improved precision, efficiency, and adaptability, eventually improving production high quality and decreasing functional prices through advanced automation solutions.

Can Robotic Vision Equipments Be Integrated With Existing Production Tools?

Robotic vision systems can undoubtedly be incorporated with existing production equipment. This combination improves functional performance, permitting seamless partnership in between conventional machinery and advanced visual modern technology, inevitably boosting general production processes and end results.

What Are the Expenses Connected With Carrying Out Robotic Vision Solutions?

The costs connected with carrying out robotic vision options vary substantially, influenced by variables such as system complexity, called for software, equipment parts, assimilation with existing machinery, and continuous upkeep expenses, eventually influencing general return on financial investment.

Just how Do Upkeep and Support for Robotic Vision Systems Job?

Maintenance and assistance for robotic vision systems entail routine software application updates, equipment inspections, and troubleshooting. optical fibre diameter analyser. Suppliers normally provide service arrangements, guaranteeing timely assistance and decreasing downtime to preserve peak performance and integrity in industrial applications